Safety Tips for Preventing Secondary Injury

- Wear proper personal protective equipment (PPE) depending on the job. Such as closed toe shoes, safety glasses, and long pants. Pay attention to fitting.

- Wear gloves, if needed, to prevent skin irritants, cuts, or other contaminants. Replace gloves if stretched, ragged, or torn.

- When working in an environment with dust, mists, or fumes, always wear a respirator that fits.

- Wear the proper respirator for the right job such as working with pesticides, dust, or livestock.

- Fit the tool to the user, not the user to the tool.

- Modify the activity so you are not doing a motion repetitively. If needed, take frequent breaks or alternate tasks.

- If you feel pain while doing the activity, consult an occupational therapist to discuss how to change the task.

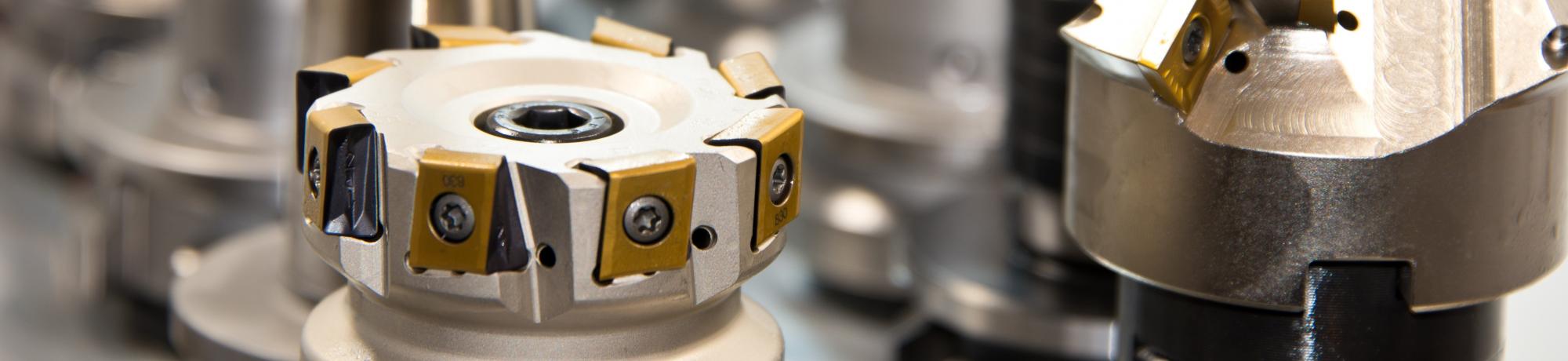

- Routinely inspect tools for damage that can cause accidents. Do not use damaged tools.

- If a tool is damaged, put a tag with “DO NOT OPERATE” red tag to prevent yourself and others from accidentally using the tool.

- When fixing or cleaning machinery, remember to lockout-tag out.

- Shut off electricity before working on any electrical equipment.

- Do not put electrical cords under carpets, this creates a fire hazard.

- Use the right tool for the job. Use hammer to hammer things in, not a screwdriver or wrench.

- Clean tools and store in designated areas at the end of each use.

- When cutting, cut away from the body facing sharp objects away from you.

- Keep walkways and work areas clear from clutter, loose objects, or obstacles that could create tripping or slipping hazards.